Hydrogen Engine Solutions

We offer a full range of solutions for Hydrogen Engine Hardware & Software, up to the complete integration into your products.

About our

H₂ Engine Solutions

The highly-skilled workforce at Dumarey Hydrocells have used all our gathered experience in engine and controller development to create a full range of Hydrogen Engine and Software solutions. We believe that in order for the world to continue its progression towards sustainable energy, it is imperative that we have effective and practical solutions for decarbonizing a wide range of applications (on-highway, off-highway, marine). In doing so, we can combine the cleanliness of hydrogen with the tested efficiency and convenience of well-established engine technologies, leveraging their wide industrial footprint, skilled workforce, as well as the servicing network.

Read on to find out how our team are developing — from concept to full-scale production — the technologies which will enable the complete integration of hydrogen solutions into your products.

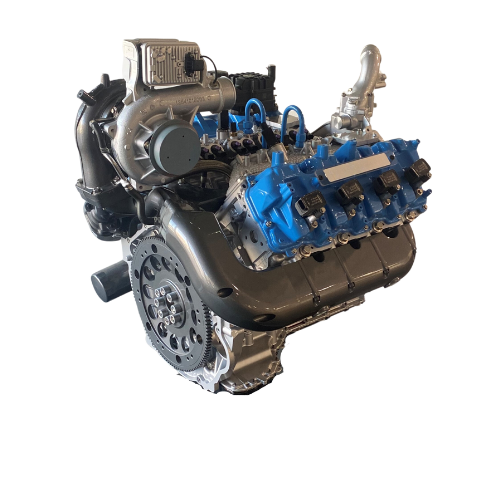

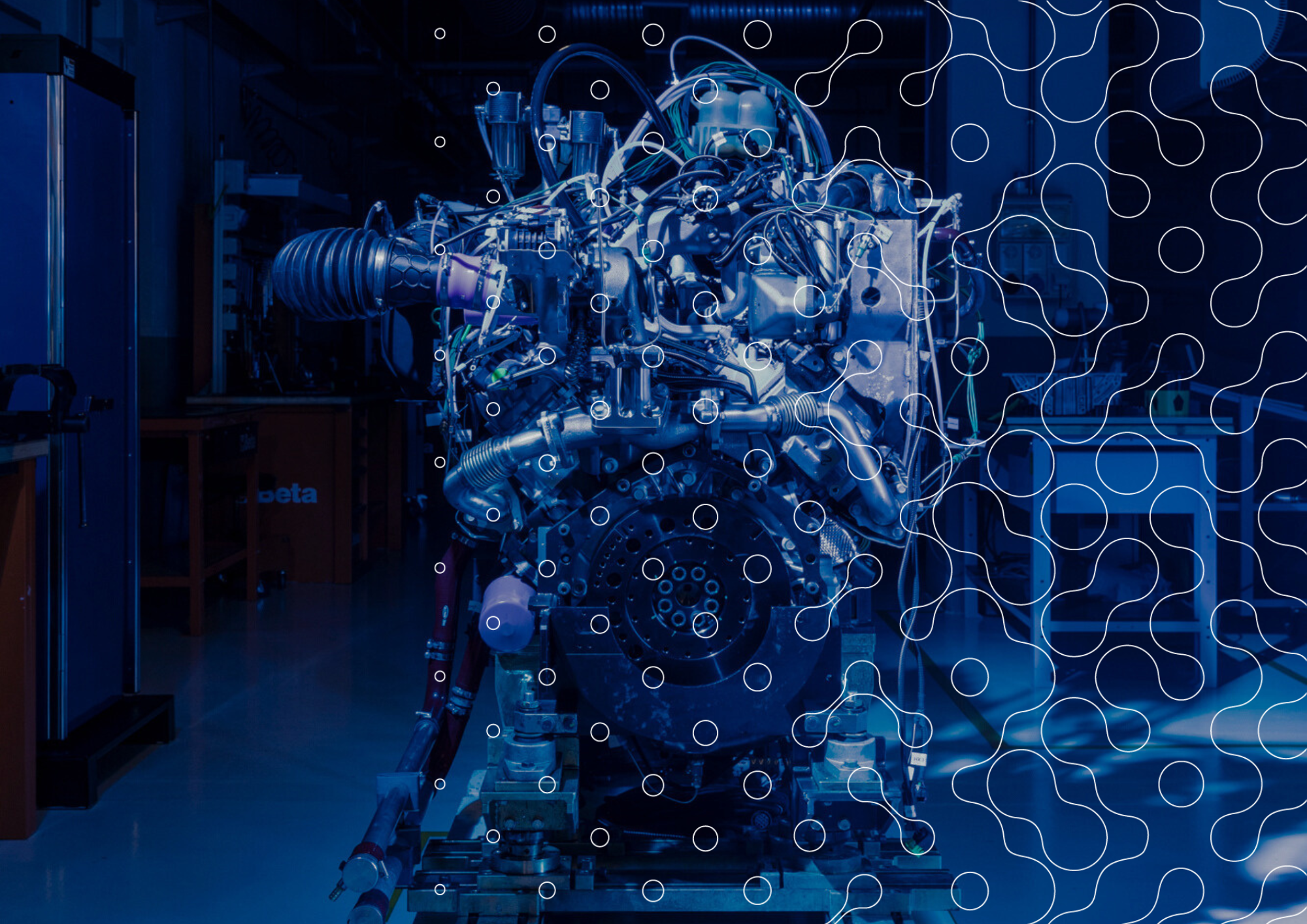

The Hydrogen Engine

Starting from the well-known and reliable V8 6.6l GM engine, we developed a state-of-the-art hydrogen engine.

Off-highway

Engine Type: V8 6.6 l

Dry Weight: 450 kg

Fuel System: PFI

Fuel Type: 2.7 hydrogen purity

Ignition: Spark Plug

Power: 250 kW @ 3000 rpm

Power Generation

Engine Type: V8 6.6 l

Dry Weight: 450 kg

Fuel System: PFI

Fuel Type: 2.7 hydrogen purity

Ignition: Spark Plug

Stand by Power at 50-60 Hz: 100 kW @ 1500rpm (50 Hz)

110 kW @ 1800rpm (60 Hz)

Marine

Engine Type: V8 6.6 l

Dry Weight: 560 kg

Fuel System: PFI

Fuel Type: 2.7 hydrogen purity

Ignition: Spark Plug

Power: 250 kW @ 3000 rpm

The Engine Control Unit

(HW & SW) for H₂-ICE

The Dumarey Electronic Platform is a 12V/24V Electronic Control Unit with high integrated drivers for Solenoid Control Valves (boosted and battery direct), DC Motors controller, flexible analog and digital sensors signal acquisition, CAN, LIN, SENT and Ethernet communication busses using a hexacore microprocessor.

With multi-purpose electronic controller based on flexible and scalable Hardware / Firmware and real-time embedded SW algorithms, it can control multiple types of propulsion and energy systems. This modular SW approach, AutoSAR based, is compliant with even the strictest automotive safety standards and cybersecurity requirements. It uses high-end connectivity to collect and transfer acquired data to the Cloud for data-driven analysis, such as fleet monitoring, root cause analysis and predictive maintenance.

6V / 16V @12V system

10V / 32V @24V system

58V @24V system

46000 Alloy or AISi9Cu

(sealed housing with Gore-Tex membrane; internally AC coupled with Power GND)

– PFI Injectors

– Pressure Control Valve

– Valves requiring current recirculation

– 4x CAN_FD

– 3x LIN

– 1x Ethernet

Key benefits

Durability

Capability to operate at Heavy Duty conditions for prolonged time & in harsh environment

No comprimise

No compromise in driving range, payload and reliability

Refueling time

Quick refueling time, comparable to fossil fuel

In house

In-house SW & Calibration for customized applications

Flexible

Flexible platform architecture for Direct Injection & Port Fuel Injection systems

Model-based approach

Model-based approach for embedded SW development

Sound experience

Improve/keep sound experience of existing engine

Autosar compliant

Autosar compliant

Publicly available articles & papers

PUNCH Hydrogen Internal Combustion Engine & KERS: an Appealing Value-Proposition for Green Power Pack

Hydrogen ICE – an appealing value proposition for sustainable mobility

Ultra-lean Combustion System Optimization for H2-fuelled ICEs via Synergistic Application of 1D- and 3D-CFD

H2-ICE: a sustainable powertrain for reaching net-zero carbon emissions

Synergetic application of 0/1/3D-CFD approaches for hydrogen-fueled spark ignition engine simulation

PUNCH H2-ICE & Flybrid KERS for decarbonizing off-highway applications

Review and assessment of the materials’ compatibility for rubbers and elastomers in hydrogen internal combustion engines

Experimental Investigation of Hydrogen Combustion in a Single Cylinder PFI Engine

White Paper:

"Hydrogen Engine: Market Perspective in Europe"

As part of the growing commitment to energy transition and carbon emissions reduction, we have explored the potential of hydrogen internal combustion engines market in Europe with Accenture Italia.

Read more here:

"Hydrogen Engine: Market perspective in Europe"

Academia Meets Industry for a New Generation of H2 ICE - Politecnico di Torino & Dumarey

Dumarey Hydrocells and Politecnico di Torino are teaming up to push the boundaries of research in hydrogen internal combustion engines. Stemming from their longstanding relationship, which began when current Dumarey Hydrocells headquarters was a General Motors research and development centre, the collaboration represents a blend of industry experience and academic insight.